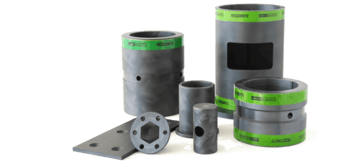

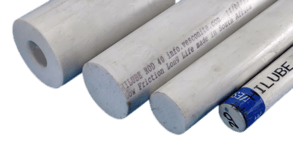

Vesconite and Vesconite Hilube

Vesconite is a self-lubricating engineering polymer that lasts 8 to 10 times longer than brass or bronze, provided the shaft rotation is not excessive. It’s ideal in underwater, dusty, and dirty environments. Vesconite works extremely well submerged in water and various fluids, and also has excellent chemical and electrical insulating properties. Applications include subsea equipment, turbine and mud pumps, rudders and propeller shafts, stabilisers, drilling equipment, and hanger bearings.

Vesconite Hilube builds on the benefits of Vesconite by incorporating an internal lubricant, giving it an even lower friction coefficient. Combined with excellent dimensional stability, low wear rates, and a high load-bearing capacity, Hilube is ideal for applications with high PV (pressure × velocity) demands—four times that of standard nylon bushings.

ENGINEERING PLASTICS

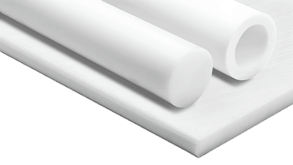

PTFE

PTFE (Teflon) – A highly versatile engineering plastic known for its

chemical inertness,

high temperature resistance,

low friction,

non-stick surface, and

excellent electrical insulation.

PTFE can also be supplied filled with bronze, glass, or carbon to meet specific application requirements.

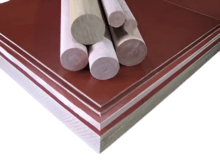

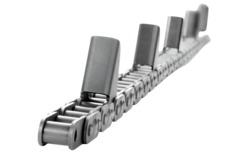

Polyethylene

Polyethylene (HDPE and UHMWPE) – Supplied in both high and ultra-high densities, this material is ideal for

wear strips,

chain guides, and other components in

industrial,

railway, and

agricultural applications.

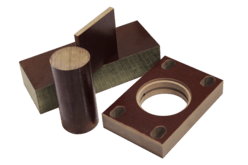

Celeron

A composite laminate offered in fabric- or paper-based formats. Fabric-based grades are suited to

mechanical uses such as bushes and wear strips, while paper-based grades are suitable for

electrical insulation under normal to high current. Multiple grades are available depending on your application.

More Engineering Plastics

Engineering plastics cover a wide spectrum of materials engineered for specific mechanical, thermal, or chemical properties. If you have a particular application in mind, please feel free to reach out—we will gladly assist with material selection.